Phone:024-25312227

Fax:024-25312227

Zip code:110141

E-mail:491189683@qq.com

|

|

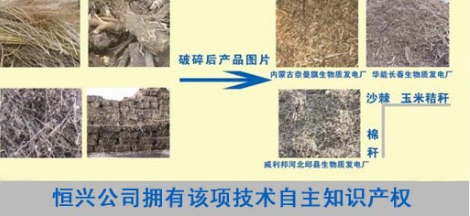

Our Company Certified by ISO9001:2000 International Quality System Large-scale Stalk Crusher The Large-scale Stalk Crusher, with 20t/h capacity, researched and developed by Shenyang Hengxing Machinery Co., Ltd. is currently deployed in several power grids such as the CHNG Changchun Thermal Power Plant, Guodian Tangyuan Biomass Power Plant and Hebei Weilibang Biomass Power Plant. 1. Low Carbon Energy Efficient Biomass Power Generation Stalk, brush wood etc. resources have similar combustion heat value as coal, and carbon emission amount is only 10% of coal. Once crushed, materials like stalk, brush wood etc.can be used as fuel to generate power. Significant social and economic value can be reaped leveraging advance energy efficient technology in biomass power generation. Thus, this low carbon enery efficient Biomass Power Generation technology is able to contribute significantly to sustainable development. The Large-scale Stalk Crusher, with intellectual property right held by our company, comes complete with material feeding, crushing and de-dusting, local and remote control and monitoring functions. It allows continous operations, produces stable crushing performance, is productive, requires low labor intensity, is safe and reliable. It is the ideal equipment to accomplish low carbon energy efficient Biomass Power Generation. 2. Solves Stalk Crush Problems Completely This patented product – Large-scale Stalk Crusher solves the problem of insufficient output of existing versions of crushers, i.e. making a breakthrough in the current technology. Material crushing has been a bottleneck in the domestic biomass power generation process. Some of the common problems encountered by existing crushers include machine jam and discharge size exceeding standard when the machine is overloaded, storage bin jams, distribution spiral winding problem etc. All these factors restricted the progress of the biomass energy program. Before the availability of this Large-scale Stalk Crusher, many biomass power plants in China operates by purchasing feed stock resulting in higher operating cost. Other commom challenges include feed stock price fluctuations and unpredictable delivery schedules etc. Power plants are typically supported by many small-size crushing stations (each of capacity: 5000~7000t/year) scattered around the nearby region. These crushing stations are operated by local peasants using diesel engine grass-cutters and is impossible for them to invest on dedusting equipment. The local enviroment agency is oblivious to this situation and is negligent in their management. The lack of dedusting function poses a serious health hazard to the operators as stalk has high dust content causing a single wok unit to exceed the dust content standard by few hundreds times. Dust particles generated during the crushing process will disperse easily in the atomosphere thus causing serious environmental pollution. The General Engineer of CHNG Jilin Co., concluded at an annual appreciation convention that: “Presently, many biomass power plants in China rely on intermediaries to purchase feed stock. Everyone knows for a fact that this is not cost efficient. What can we do to break free from the vicious cycle of price fluctuations and high supply cost, and also be able to contain dust pollution caused by the crushing process? Power plants must gain autonomy in cost control by using the business model of consolidating raw materials bulk purchaes, centralise crushing activities, invest in effective dedusting technology to control dust pollution-such is the promise of biomass power plant to the sosiety…….CHNG Changchun Biomass Power Plant turns biowaste into wealth, and is the pioneer in achieving a balance in protecting our environment and benefiting the enterprise!” Compared to the operating model of purchasing feed stock, the business model of consolidated procurement of materials and centralised crushing (coupled with effective dedusting installation) is able to achieve a savings of 20.44 million yuan/year and reduces dust emission by 432 ton/year. Energy-efficiency, eco-friendliness and enhancing productivity are congruent with the principles of mass-production. Biomss Power Plants will find that this machine is the solution to resolving their various material-related challenges. 3. Large-scale Stalk Crusher in Operation and Award

If you want to get the field running video information of Large-scale Stalk Crusher of our company, please click at: http://v.youku.com/v_show/id_XMjEwNjA2ODE2.html 4. Key Characteristics (1)Adopting a dual-roller design, it uses a high speed fly-cutter to cut and crush materials and quickly discharges the materials using a special guiding device. It is able to satisfy the throughput requiements with its sensible design, reliable performance, granular crushing size, user-friendliness, ease of mainteance, and long cutter life span. (2)The shovel loader is able to directly feed the conveyor belt with feed stock, and the belt in turns send the materials directly to the main machine for crushing. It is able to thotoughly cut and crush bulk and packed stalks, long brush wood and roots into the speified granularity all at once. (3)The attached deduster is able to abosorb and eliminate the dust in the crush. (4)It is fully automated, efficient and productive, requires minimal human intervention, is safe and reliable. 5. Materials Suitable for Crushing (1). Stalk: corn stalk, sorghum stalk, cotton stalk, sunflower stalk, sugarcane leaf; (2). Brush wood: sea buckthorn, yellow willow; (3). Forest wood: root, bark, leaf; (4). Waste: industrial, living garbage (5). Coal, minerals etc. materials.

六、 Lectotype table of comparisons and main parameter

选型对照表及主要参数

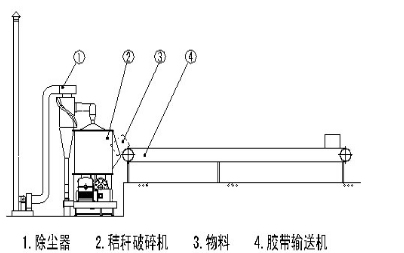

七、 Diagram of Crusher System

Procedures (1). Material is sent to rubber belt conveyor; (2). Rubber belt conveyor sends material to crusher for crushing; (3). Crusher crushes material into suitable size; (4). The deduster removes residue dust and is complaint to the international environment standards. |

[返回]